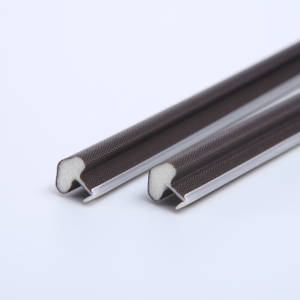

PU Foam Seal Door Weatherstripping Product parameter

1. Material Composition:

High-density Polyurethane (PU) Foam with closed-cell structure for superior insulation and durability.

2. Compression Set Resistance:

High compression recovery, retaining 90% or more of its original thickness after compression, ensuring a long-lasting and reliable seal.

3. Temperature Range:

Operational temperature range: -40°F to 160°F (-40°C to 70°C), making it suitable for diverse climates and conditions.

4. Color Options:

Commonly available in neutral colors such as white, brown, black, and grey to match various door frames and aesthetics.

5. Installation Type:

Kerf-In Style: Fits directly into the kerf slot on the door frame, requiring no adhesive.

Self-Adhesive Backing: Equipped with strong, pressure-sensitive adhesive for easy peel-and-stick installation.

6. UV and Weather Resistance:

Treated with UV inhibitors and weather-resistant coatings to prevent degradation from sunlight, moisture, and extreme weather conditions.

7. Water Absorption Rate:

A low water absorption rate, typically less than 5% by volume, ensures that the foam remains effective in sealing against water and moisture.

8. Water Absorption Rate:

A low water absorption rate, typically less than 5% by volume, ensures that the foam remains effective in sealing against water and moisture.

9. Sound Insulation Rating:

Noise Reduction Coefficient (NRC): Typically ranges from 0.35 to 0.45, providing effective soundproofing capabilities.

10. Hardness (Shore A):

Typically between 10 to 25 Shore A, offering a balance of softness for compression and firmness for durability.