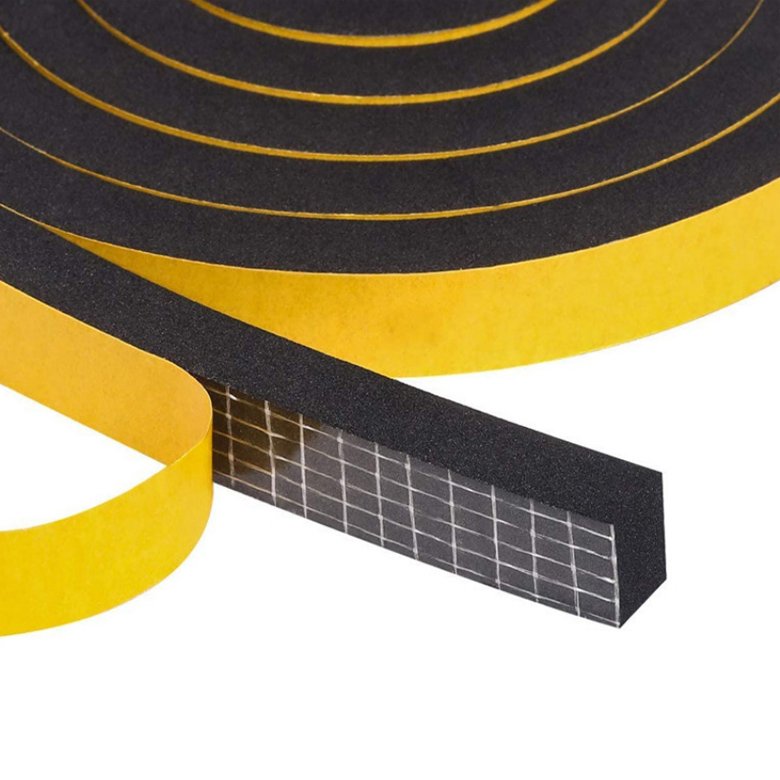

EPDM Foam Rubbrer Seal Strip

Product Superiority

1. Made in rubber EPDM.

2. Excellent inherent high and low-temperature ranges.

3. Typically -60 ° C to +120 ° C for standard compounds.

4. EPDM is essentially resistant to attack by oxygen, UV, ozone, and extreme weather environments, and provides an extended service under these conditions.

5. Chemical resistance, resistant to many solvents.

6. Good resistance to many corrosive chemicals.

Product Description

EPDM Foam Rubber Seal Strip manufacturer

- When it comes to sealing solutions, Kinglin manufacturer’s EPDM foam rubber seal strips stand out for their superior performance, durability, and versatility. With their excellent weather resistance and flexibility, they serve a wide range of industries, including automotive, construction, and manufacturing.

- As a trusted manufacturer, we offer advanced manufacturing capabilities, customization options, and a commitment to delivering high-quality products. Choose us as your reliable partner for EPDM foam rubber seal strips that meet your sealing requirements with precision and excellence.

- It has good elasticity and compression deformation resistance and excellent aging resistance. Excellent flame retardant performance, low smoke, and low toxicity; stable product performance, and high dimensional accuracy.

Applications of EPDM Foam Rubber Seal Strips

- Automotive: door, truck, truck crap, window seals spacers for wheel wells, window weather stripping

- Building products: curtain wall frames, OEM window seals, door seals slider door seals, tract and channel seals

- Window and door: various door seals, edge guards, egress window frames, and garage door seals.

Benefits

EPDM foam rubber seal strips possess several key advantages that make them a popular choice for sealing applications:

- Excellent Weather Resistance:

EPDM foam rubber seal strips exhibit exceptional resistance to UV rays, ozone, extreme temperatures, and harsh weather conditions. - Superior Durability:

Our EPDM foam rubber seal strips are engineered to withstand repeated compression, stretching, and bending without losing their sealing capabilities. - Flexibility and Versatility:

They can effectively seal gaps, joints, and edges, providing a seamless barrier against moisture, dust, noise, and vibration.

Why Choose Us as Your EPDM Foam Rubber Seal Strip Manufacturer

- Advanced Manufacturing Capabilities:

Our state-of-the-art manufacturing facility is equipped with cutting-edge technology and machinery, enabling us to produce EPDM foam rubber seal strips with precision and consistency. We adhere to stringent quality control measures to ensure that our products meet the highest industry standards. - Customization Options:

We understand that different applications have unique sealing requirements. Therefore, we offer customization options for EPDM foam rubber seal strips, including dimensions, shapes, colors, and adhesive backing, to suit specific client needs. - Commitment to Quality:

Quality is at the core of our manufacturing process. We source premium-grade EPDM materials and employ skilled professionals to ensure that our seal strips deliver exceptional performance, durability, and reliability.