Turbocharged vehicles require charge air coolers to lower intake air temperatures for optimal combustion and power. These air-to-air heat exchangers rely on high quality charge air cooler hoses to route hot compressed air from the turbocharger through the cooler.

Additionally, the charge air cooling system is vital for getting max power and performance from a turbocharged engine. Quality charge air cooler hoses prevent leaks while resisting heat and pressure extremes. In this article, we’ll look at charge air cooler hose design, materials, and proper installation tips to keep your turbo engine running cool.

What is a Charge Air Cooler?

A charge air cooler (also called an intercooler) is a small radiator-like device that removes heat from the compressed air charge exiting the turbo. Cooling this pressurized intake air increases its density for more oxygen per combustion cycle. Denser air allows turning up the engine power without detonation.

The charge cooler uses an arrangement of thin cooling fins and tubes. Hot inlet air from the turbo flows through the fins and gets cooled by ambient air flowing over the outside of the cooler. Cooled air then exits via the outlet side to the intake manifold and cylinders.

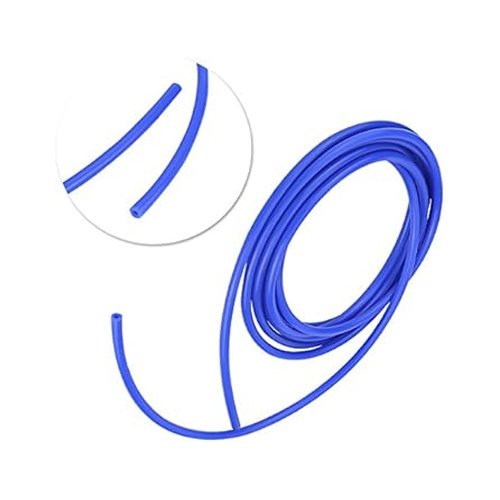

High Quality Charge Air Cooler Hoses

Reinforced silicone or stainless steel braided hoses are used to connect the turbo outlet to the charge air cooler inlet, and the cooler outlet to the engine intake. Key hose requirements include:

- High heat resistance – Handles exposure to air temps exceeding 500°F from the turbo.

- Durability – Withstands boost pressures exceeding 15 PSI.

- Abrasion resistance – Stainless steel braiding prevents scuffing and damage.

- Crush resistance – Maintains airflow under clamps and pulleys.

- Low permeability – Prevent pressure loss and leakage.

- Ozone/UV resistance – No cracked tubing from sun exposure.

Proper installation and the use of torque-limited clamps are also crucial to avoid hose failures that could lead to disastrous engine damage from overheating or debris ingestion.

Benefits of Efficient Charge Air Cooling

Effective charge air cooling provides several performance benefits:

- Increases horsepower and torque output.

- Prevents pre-ignition and detonation.

- Allows running higher boost safely.

- Improves fuel efficiency due to cooler, denser intake air.

- Reduces engine stress from excessive heat.

- Helps maintain air-fuel ratios and emissions control.

Signs of Worn Charge Air Cooler Hoses

Watch for these indications that your charge air cooler hose need replacement:

- Brittle, cracking outer cover revealing bald inner tube.

- Collapsed hoses restricting airflow due to internal corrosion.

- White powder residue from hose breakdown contaminating intake.

- Severe heat and pressure deformities of the hose.

- Leaking connections caused by end fitting corrosion.

- Reduced turbo boost pressure caused by leaks.

Proper Charge Air Hose Installation

Follow these tips for correct charge air hose routing and clamping:

- Select hoses rated for at least 60 PSI and 500°F.

- Ensure proper hose bend radius – no kinks or tight bends.

- Keep hoses away from exhaust – use heat shields if necessary.

- Use alleviated clamps sized for the hose diameter.

- Torque clamps to 8-12 ft-lbs for security without collapsing hose.

- Check for leaks and hose condition during routine maintenance.