In the realm of industrial equipment and machinery, reliable connections are essential for ensuring efficient operation and preventing costly downtime. This comprehensive guide delves into the properties, advantages, and applications of 4-inch silicone couplers, highlighting their versatility and effectiveness in various industrial settings.

Understanding 4 Inch Silicone Couplers:

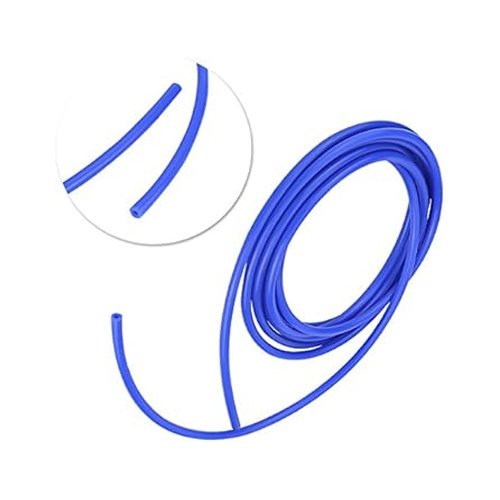

4 inch silicone couplers are flexible, cylindrical connectors designed to join two pipes or hoses of the same diameter. They are manufactured from high-quality silicone rubber, known for its exceptional flexibility, durability, and resistance to extreme temperatures and harsh chemicals.

Properties of 4 Inch Silicone Couplers:

Flexibility: Silicone couplers offer excellent flexibility, allowing for easy installation and accommodation of misalignments, vibrations, and movements in piping systems.

Temperature Resistance: These couplers can withstand a wide range of temperatures, typically from -60°C to 260°C (-76°F to 500°F), making them suitable for both high-temperature and low-temperature applications.

Chemical Resistance: Silicone couplers exhibit superior resistance to a variety of chemicals, including acids, alkalis, oils, and solvents, ensuring long-lasting performance in demanding environments.

Pressure Rating: They are designed to handle various pressure ratings, from low-pressure applications to high-pressure systems, depending on the specific design and material composition.

Non-Conductive: Silicone couplers are non-conductive, making them ideal for applications where electrical insulation is required.

Advantages of Using 4 Inch Silicone Couplers:

Versatility: China 4 inch silicone coupler is highly versatile and can be used in a wide range of industries, including chemical processing, pharmaceutical manufacturing, food and beverage, automotive, and aerospace.

Easy Installation: Their flexibility and simple design allow for quick and hassle-free installation, reducing downtime during maintenance or repairs.

Durability: Silicone couplers are highly durable and resistant to wear and tear, ensuring a long service life even in challenging conditions.

Leak-Proof Connections: The tight seal provided by silicone couplers prevents leaks and ensures the integrity of the piping system.

Cost-Effectiveness: Compared to metal or rigid couplers, silicone couplers offer a cost-effective solution while maintaining high performance and reliability.

Applications of 4 Inch Silicone Couplers:

Chemical Processing: Used to connect pipes and hoses in chemical plants, where resistance to corrosive chemicals is crucial.

Pharmaceutical Manufacturing: Ideal for transferring fluids and powders in pharmaceutical production facilities, maintaining sterility and cleanliness.

Food and Beverage Industry: Suitable for conveying food products, beverages, and liquids in hygienic and sanitary conditions.

Automotive and Aerospace: Utilized in engine systems, cooling systems, and fuel lines, where flexibility and temperature resistance are essential.

HVAC Systems: Employed in heating, ventilation, and air conditioning systems to connect ducts and hoses.

Factors to Consider When Choosing 4 Inch Silicone Couplers:

Temperature Requirements: Ensure that the couplers are rated for the maximum operating temperature of the application to avoid premature failure.

Chemical Compatibility: Consider the chemical composition of the fluids or gases being transferred to select couplers with appropriate chemical resistance.

Pressure Rating: Choose couplers that can withstand the pressure requirements of the system to prevent leaks and maintain safety.

Size and Dimensions: Verify the inner diameter and length of the couplers to ensure proper fit and compatibility with the connected pipes or hoses.