V-Band-Klemmen haben viele Vorteile wie eine schnellere Installation und Entfernung, Keine Leckage, Hochdruckbeständigkeit, usw. Dieser Leitfaden führt Sie durch ihre Vorteile, Vergleiche, Professionelle Tipps und Installation im Detail.

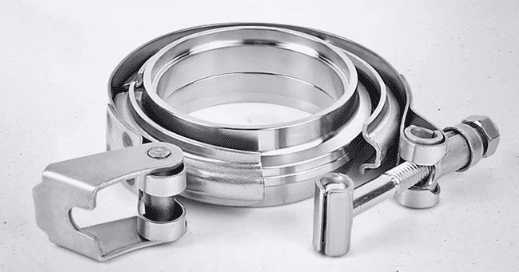

A V-band clamp is a type of clamp used to create a strong seal between pipe connections. It consists of a V-shaped metal band and flanges. When you tighten the clamp’s nut, it squeezes the V-angle flanges together, applying even pressure all the way around the connection. This design eliminates the need for bolts or gaskets, which makes it great for high-vibration, high-heat applications like exhaust and turbo systems.

Let’s dig into how V-band clamps work and how to choose, install, usw.

How does the V-band work?

The V-band clamp system is made up of three main parts: two flanges (welded to the ends of the pipes) and the clamp. The flanges are shaped like a cone with a V in the middle. When you tighten the clamp nut, it pulls the flanges together. The V-angle causes the clamp to wedge together, creating even pressure all the way around and making a tight seal that won’t leak.

Because of the way it wedges together, it can handle a little bit of misalignment and vibration, which makes it perfect for automotive applications where things get hot and stressful.

Are V-band clamps good for exhaust?

You bet! V-band clamps are popular in performance and race exhaust systems because they:

Make it easy to take things apart and put them back together

Don’t require gaskets or sealant

Stay tight and in place even under high heat and vibration

Make a good, tight connection that looks clean

V-band systems are more reliable over time, especially in V-band exhaust and turbo setups, than band clamps or flanges.

What is a V-band turbo?

In einem V-Band-Turbo-Setup, Die V-Bandschelle dient zur Verbindung des Turbinengehäuses mit dem Fallrohr oder Mittelrohr. Dadurch können Sie Turbos schneller austauschen und Probleme wie Abgaslecks am Turboflansch werden vermieden. Dies ist besonders praktisch in engen Motorräumen, in denen es schwierig ist, einen Schraubenschlüssel an die Schrauben zu bekommen.

Bonus: Bei V-Band-Turbos lässt sich das Gehäuse normalerweise um 360° drehen, was das Takten des Gehäuses erleichtert.

So installieren Sie eine V-Band-Klemme

Beide Flansche an die Rohrenden anschweißen, Stellen Sie sicher, dass sie perfekt ausgerichtet sind.

Tragen Sie Anti-Seize auf die Klemmmutter auf, damit es nicht nervt.

Setzen Sie die Flansche zusammen und setzen Sie die Klemme ein.

Ziehen Sie die Klemmmutter gleichmäßig an. Verwenden Sie einen Drehmomentschlüssel, um sicherzustellen, dass er fest genug sitzt.

Mit Rauch oder Seifenlauge auf Undichtigkeiten prüfen.

Vor- und Nachteile der Verwendung von V-Band-Klemmen

Vorteile

- Leckt nicht unter hohem Druck

- Einfach zusammenzubauen/zu zerlegen

- Keine Dichtungen erforderlich

- Lässt sich drehen, um es perfekt auszurichten

Nachteile

- Der Einstieg ist teurer

- Man muss es schweißen

- Kann zu fest angezogen und zerstört werden

- Wenn Sie es nicht richtig einsetzen, es kann sich lösen

Häufige Fehler bei V-Band-Klemmen und wie man sie vermeidet

- Überdrehen: Entfernt Fäden oder verzieht die Klemme

- Unterziehen: Verursacht Undichtigkeiten und Lockerung durch Vibration

- Fehlausrichtung der Flansche: Verhindert eine ordnungsgemäße Abdichtung und verursacht Spannungsbrüche

- Kein Anti-Seize: Macht das Entfernen zum Albtraum

Vermeiden Sie diese Probleme, indem Sie sich Zeit nehmen und einen Drehmomentschlüssel verwenden.